Contract manufacturing for precision parts

Our services as a contract manufacturer

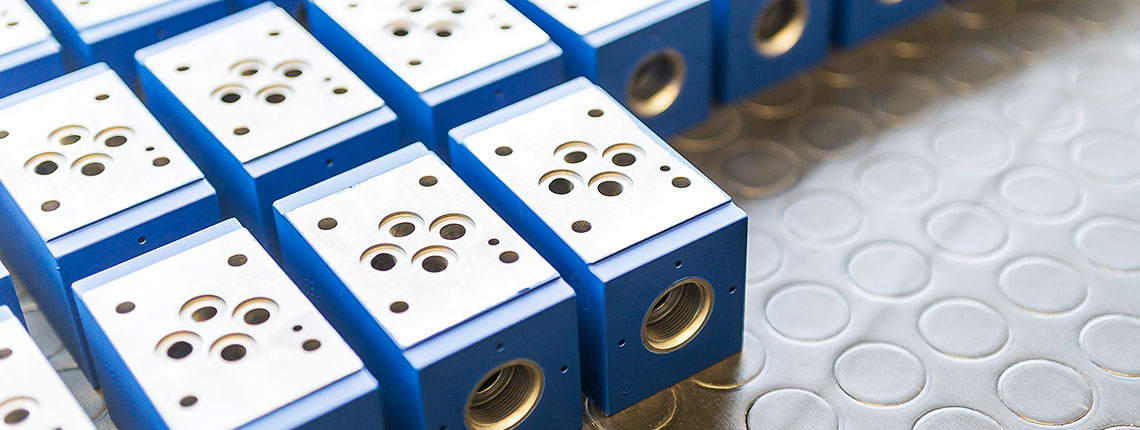

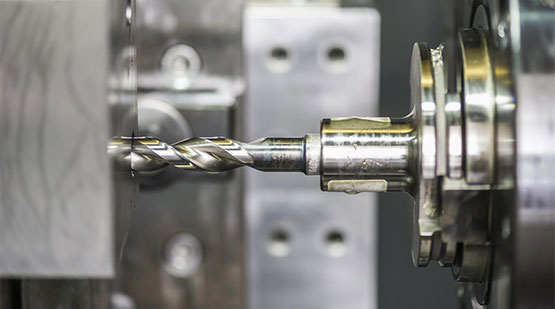

Our employees’ know-how in the field of contract manufacturing flows into the manufacture of high-quality individual components and assemblies for well-known manufacturers of hydraulics systems. The complete manufacture of installable components involves the entire process chain, from machining manufacturing to microfinishing, deburring, cleaning and surface treatment, to the careful assembly of hydraulic parts. Tens of thousands of units are produced from individual parts to manufacturing batch sizes. The company’s own tool grinding shop also manufactures complex solid carbide tools which are used for serial manufacturing for boring, lowering, reaming or milling

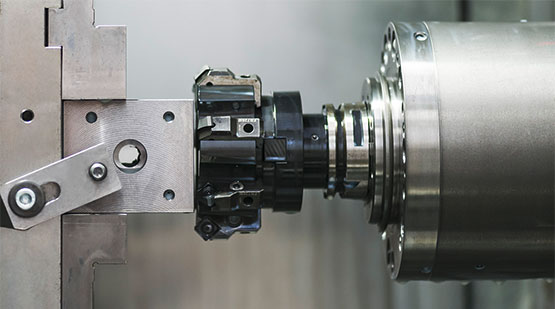

Mill

- Materials: Cast iron and spheroidal graphite, steel, aluminium

- Geometries: Fine surface roughness and high demands for evenness

- Precision: Precision mechanical processing with tolerances calculated to thousandths.

- Unit weights: Up to ca. 80 kg

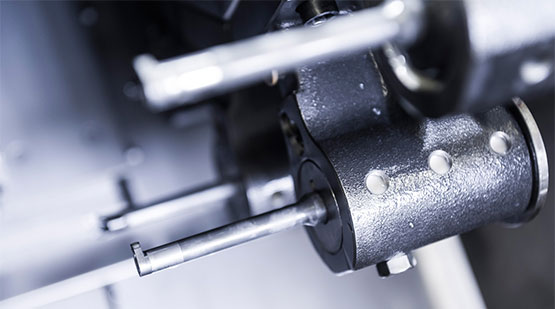

Turn

- Materials: Cast iron and spheroidal graphite, steel, aluminium

- Geometries: Spool bores with control edge (range of tolerance ±0.005)

- Precision: Precision mechanical processing with tolerances calculated to thousandths.

- Unit weights: Up to ca. 12 kg

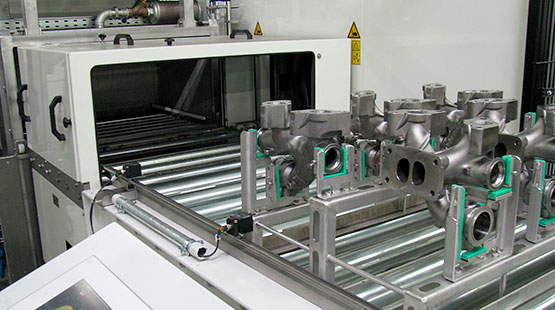

Clean

- Process: Wet cleaning with unicameral liquid agitation machine for chlorinated hydrocarbons

- Technical cleanliness The company’s own cleanliness laboratory for internal analysis in accordance with VDA 19 as well as special analyses by client request

- Aqueous industrial, automated cleaning system with integrated vacuum drying system

- Industrial and automated hydrocarbon cleaning system

- Washstands for manual final cleaning

Paint

- Process: Compressed air spray technology

Drill

- Materials: Cast iron and spheroidal graphite, steel, aluminium

- Geometry and precision: conventional boring, special stepped boring with several fits (shape and position tolerances in µ zone)

Mount

- Assemble stages: Closing connection holes, assembly of guide and sealing rings, set-up and adjustments for hydraulic components

Pack

- Packaging in environmentally suitable single-use or reusable packaging according to client’s requirements and practicality

- Packaging with temporary corrosion protection as insert material in client-specific transport containers (where applicable, also individually in VCI foil bags).

Deutsch

Deutsch

English

English